- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

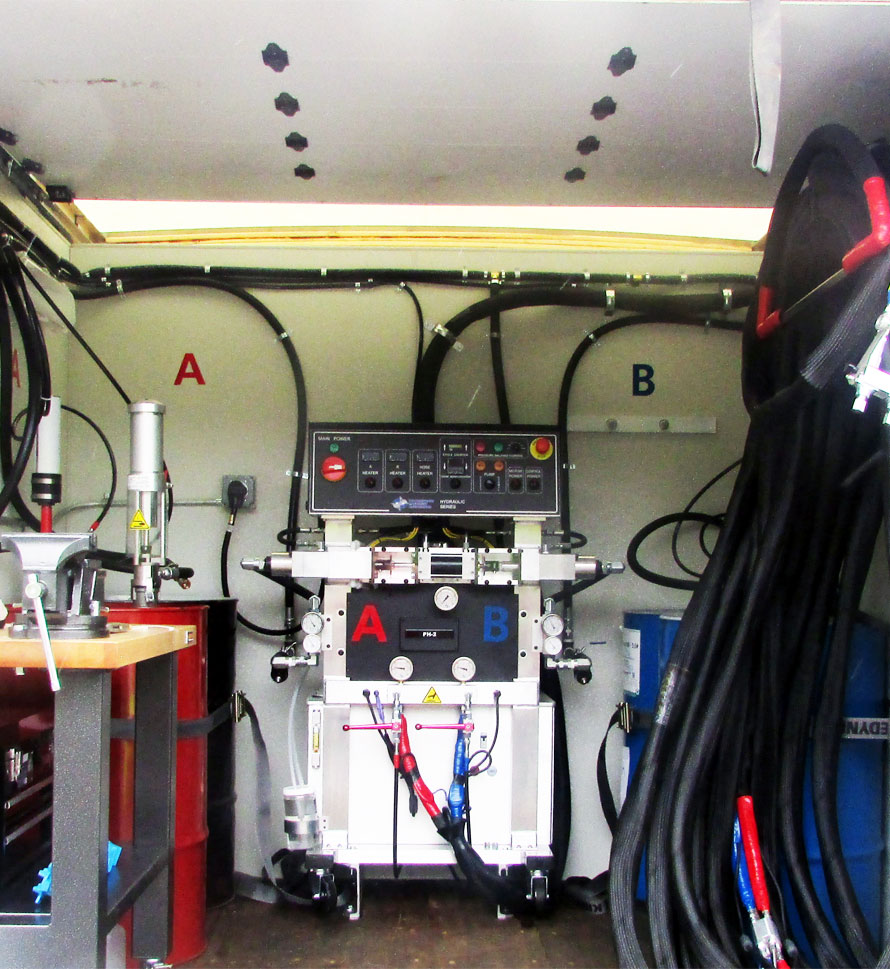

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Case Studies

- Contact

Prime Resins News

3 Simple Ways to End I&I in Collection Structures

3 Simple Ways to End I&I in Collection Structures - Efficiently, Economically, and Perpetually

The U.S. Environmental Protection Agency has deemed that as much as 60% of groundwater infiltration arrives through sanitary sewer manholes. For over 50 years, chemical grouting is one of the oldest techniques used to stop ground water infiltration into sewer collection systems.

There are three basic methods for sealing manholes. The first, and most basic method is commonly referred to as 'oakum/ soak 'em' and is used to seal leaking cast concrete joints and pipe entry points, and manholes with missing or broken bricks. This method utilizes a water reactive urethane chemical such as Hydrogel SX and jute rope commonly known as oakum, which is mixed together to form a permanent seal. This practice is commonly around pipe interfaces or used when gaps in the structure is present and exhibiting groundwater infiltration.

A second method utilizes a low viscosity permeation (1-2 cps) AR 800 Acrylate or PR10 ACLM Acrylamide chemical. This technique requires a stainless steel plural component pump that injects the grout under pressure through the manhole (using probes or a packer) into the surrounding soil. The permeation grout does not expand, but saturate the soil immediately outside of the manhole (with a desired gel-time) that permanently stabilizes the soil and creates a barrier against ground water entering the manhole. This can even be done in moisture saturated soils, however a faster gel time may be desired.

The third method utilizes a water-reactive hydrophobic Prime Flex 920 urethane. This method requires a single-component pump to inject the grout. When mixed with water, the grout expands under pressure chasing water through the cracks subsequently filling the cracks and voids adhering to the soils outside the manhole. This hydrophobic chemical binds with the soil to offer greater tensile strengths than chemical gel grouts, thus creating what is commonly know as “grout columns”.

As mentioned, when as much as 60% of groundwater inflow and infiltration entering through vertical collection structures, the rehabilitation of aging infrastructure has never been so important. Although chemical grouting can be used as a stand-alone practice, more municipalities are combining this procedure with the rehabilitation of the structures; as these methods require a dry substrate for the application of proposed coating. With the multitude of proactive technologies in the trenchless industry, this time-tested technique of chemical grouting has been the only proven method to remediate inflow and infiltration: AT THE SOURCE.

Follow us on Twitter

Follow us on Twitter Follow us on Linked In

Follow us on Linked In Follow us on You Tube

Follow us on You Tube