- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

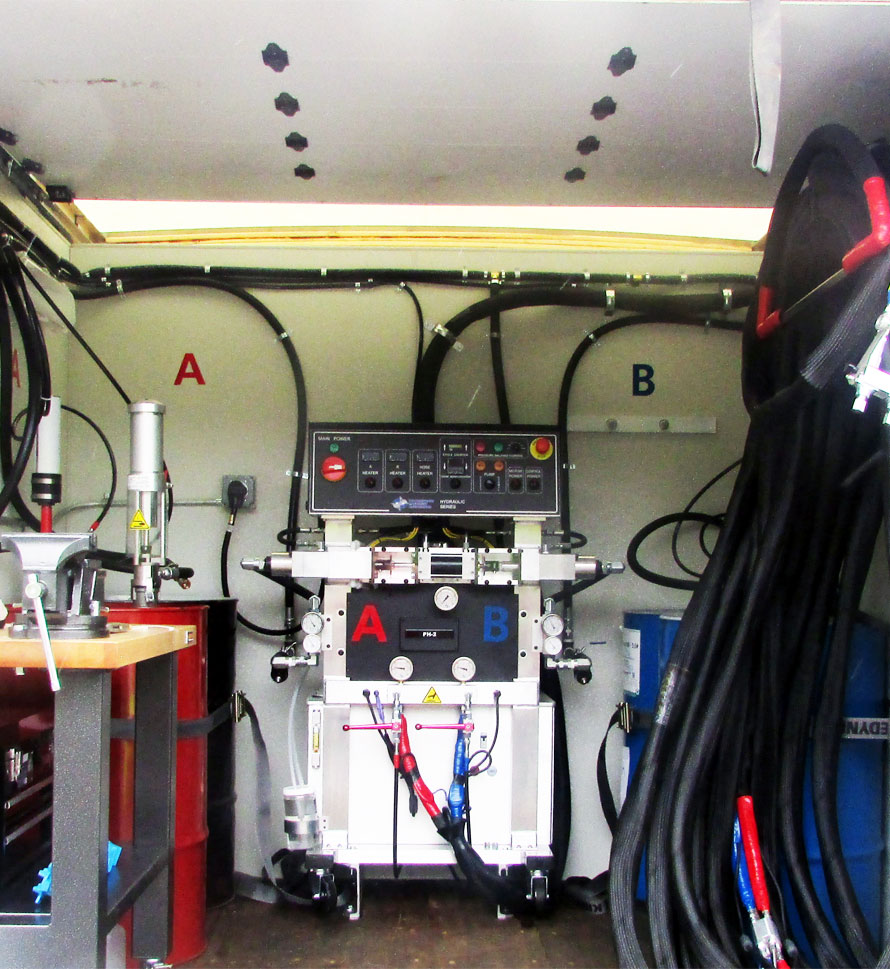

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Leak Seal Pages

Box culvert repair with chemical grouting prevents wetland impact, saves money for Tallahassee

Client: City of Tallahassee, Florida

Design Engineer: Environmental and Geotechnical Specialists, Inc. (EGS)

Contractor: Foundation Professionals of Florida, a Cal-Tech Testing, Inc. company

The City of Tallahassee had a problem with one of its streets running over a box culvert at Black Swamp. Following several heavy rainfalls, a dip in Park Avenue developed. Eventually the depression grew so pronounced that it became a traffic hazard.

City crews attempted to fix the problem several times using different methods, including replacing a section of pavement and its subgrade, and chemically grouting the culvert joints with an epoxy-based grout. These repairs did not work, however. Settlement of the roadway continued. Officials suspected that the culvert joints were leaking, so they considered completely removing the roadway to expose the box culvert. This option was very expensive and difficult. The factors included:

- state and city government did not want to close the road,

- there are existing utilities over and around the culvert, plus

- the south headwall of the culvert has a control weir used to regulate the water elevation within Black Swamp, a protected wetland.

Identify the cause

The city subsequently hired Environmental and Geotechnical Specialists Inc. to pinpoint the cause and provide emergency design and repair services that, if practical, did not involve reconstructing the roadway. EGS conducted a subsurface investigation, which included boring holes along the centerline of the road and installing temporary piezometers to measure the groundwater. Based on a series of piezometer measurements, it became clear by the drop in groundwater measured that groundwater was, in fact, leaking through the joints in the culvert and the control weir.

Consequently, EGS and the City of Tallahassee developed a plan to seal the leaking joints and fill the resulting voids along the culvert and weir sidewalls from inside of the culvert. The erosion around the leaking joints was the cause of the sinking pavement. Four main factors contributed to this decision:

- The presence of active utilities

- The desire to maintain traffic flow

- The need to control the elevation of water in the adjacent wetland

- Given the proximity to a protected wetland, the ability to use Prime Resins environmentally friendly products, which are inert when cured.

The plan

The repair had two phases. The first phase was to install a series of equally spaced holes at each joint through the culvert flange into the seal. A small injection port was installed in each hole and surface sealed. Prime Flex 900 XLV, an extremely low viscosity hydrophilic resin, was installed under pressure until it was observed exiting the adjacent port. 900 XLV reacts with water and expands to form a closed cell, watertight foam. In addition, this product complies with NSF/ANSI Standard 61 for contact with potable water. The process was repeated until all the injection ports at each joint were grouted.

In phase two, the crew identified and filled existing voids around the culvert. After grouting all the joints, they drilled small holes through the culvert sidewalls to identify and map the voids. Next, the crew installed injection ports in the culvert and weir sidewalls, and filled the voids with Prime Flex 910, an expansive, hydrophobic polyurethane that reacts with moisture to form a rock hard, watertight mass. Foundation Professionals of Florida out of Lake City, Florida, was the contractor. In addition, Prime Resins provided on-site technical service and manufacturer’s representation throughout the grouting phases.

Measuring success

After grouting, contractors measured groundwater levels with the piezometers to identify whether a drop in the groundwater table at the culvert or weir was still present. They found no decrease.

Follow up

Thirty days after the repair, the culvert and weir were inspected for leaks. Four minor weeps were detected, and these were grouted shut with 900 XLV. The structures were re-inspected after another 30 days with no signs of seepage or staining.

Outcome and benefits

Foundation Professionals sealed the leaks and settlement of the road stopped.

Several benefits resulted from the City of Tallahassee’s willingness to consider chemical grouting as a repair option. These included:

- Significant cost savings compared to excavation and reconstruction—more than $75,000,

- Reduced waste of material: targeted void filling reduced grout waste and unintended grout flow in a sensitive wetland,

- No disruption to utilities,

- No disruption of traffic: the road stayed open through the process, which would have been impossible with excavation or a traditional cement compaction grouting, and finally

- Environmental protection: contractors worked in the wet environment with no need for dewatering or other impact on the wetland water levels.