- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

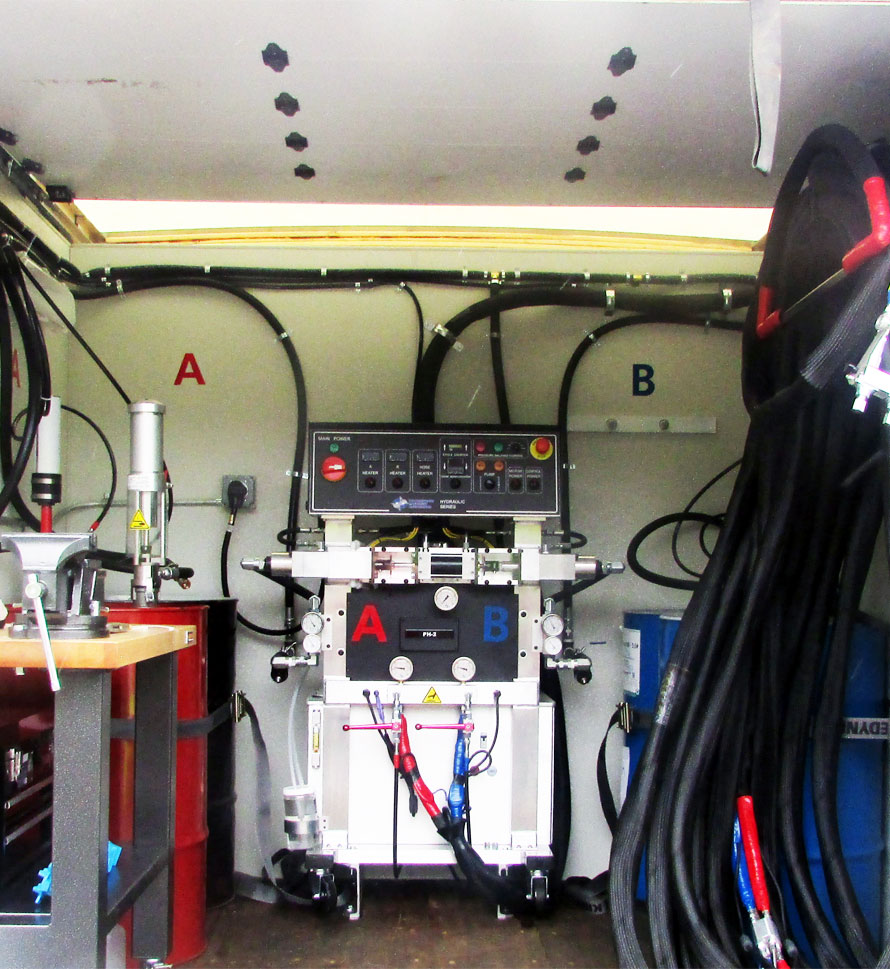

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Leak Seal Pages

Chemical Grout Seals Leaks in a Pit Excavation

Client: New York City Department of Environmental Protection

Contractor: Infrastructure Repair Service, N.J.

Sometimes the fourth time is the charm. Such was the case with a major wastewater treatment facility construction in Queens, N.Y.

Flushing Bay is located in Queens, N.Y., off the East River between LaGuardia Airport and Citi Field, home of the New York Mets. Up the Flushing Creek a few blocks and adjacent to the USTA Billie Jean King National Tennis Center sits the Flushing Bay Combined Sewer Overflow Facility. Constructed over several years and completed in 2009, the facility stores 43 million gallons of sewage beneath a recreation center and playing fields.

Injection of polyurethane grouts played a key role in the successful excavation of the 80-feet-deep, multi-acre pit.

Problem

Washouts and construction delays plagued the excavation due to leaks in the concrete support caissons. Some context is needed to explain the exact nature of the problem and its cause.

Background

Concrete caissons were poured to stabilize the soil and create the perimeter around the excavation. These caissons were formed by, first, drilling a row of deep holes around the eventual perimeter of the pit. Next, placing steel I-beams vertically inside each hole. Then, filling each hole with concrete.

Excavation crews then removed the soil layer by layer at the rate of about 25 feet per layer, exposing the wall of concrete columns. In order to properly support the pit walls, crews installed tieback anchors to stabilize the caissons. They drilled holes between the caissons and cement deadmen that were grouted in the soil outside the planned pit perimeter. Next they installed conduit sleeves in the drilled holes and pulled post-tensioned cables through. They attached and tensioned the cables to bracing beams known as walers that were welded to the I-beams within the caissons.

Springing leaks

Before the installation of the tiebacks was complete, however, problems emerged. When the pit got approximately 25 feet deep, below the level of the surrounding groundwater, water began leaking through and around the conduit sleeves into the pit. Some of the leaks were severe, gushing as much as 50 gallons of water per minute. In some places this made it impossible to continue welding the cable bracing beams.

Leaks through the tieback anchors used in excavation of an 80-ft-deep pit for the Flushing Bay CSO prevented welding. Note the water streaming from the lowest row of anchor plates. The leaks were ultimately sealed with Prime Resins polyurethanes.

Third time was not the charm

The general contractor hired a repair company who tried using cement grout to stop the water. That quickly failed. A second company was hired who tried a different grouting method. This too failed. Then a third company tried yet another method, but also could not stop the gushing leaks.

This left the general contractor in a tight spot. His project was delayed, the pit still leaked, and he had wasted time and money on repairs that didn’t work. So, the site engineer from Malcom Pirnie (now Arcadis) called Otto DeJager of Infrastructure Repair Service in New Jersey. Upon visiting the site, DeJager assured the GC that a crew from Infrastructure Repair Service could seal the leaks with no problem. “Good luck,” said the GC’s rep unenthusiastically.

Solution

DeJager decided that the most effective solution was to use Prime Flex polyurethanes from Prime Resins. He knew that on a difficult job, quality and service were important. DeJager based his decision on his own track record of more than six years using Prime Resins products that performed exceptionally every time, coupled with the knowledgeable technical services staff at Prime Resins.

How they did it

For the gushing leaks, crews from Infrastructure Repair drove 10-foot-long sections of 3/8-inch pipe back into the conduit sleeves as far as they could toward the deadman. In some places they had several pipes joined together to go back as far as possible. They used the rod essentially as a giant grout needle and injected Prime Flex 920 behind and into the sleeves. The 920 reacted with the water present and expanded to form a hard, watertight mass that sealed the sleeves.

In places where the water flow was too great, technicians used sections of hose as relief tubes, then packed the area around it with activated oakum. This is oil-free jute rope saturated with Prime Flex 900 LVSF (now 900 XLV), a hydrophilic polyurethane grout. The activated oakum technique sealed the gaps between the end of the sleeve and the anchor plate attached to the waler. They then went back and injected the relief tubes and any remaining gaps in the tensioning assembly with the 900.

“For a permanent seal I always inject 900 XLV,” says DeJager. “It makes a nice, flexible plug.”

While this all sounds relatively simple when boiled down in writing, experience and improvisation played a major role. Also, there were times when the repair work was complicated by needing to be done hanging from a basket as much as 80 feet into the pit.

Outcome

The GC called in the Infrastructure Repair crew as needed throughout the pit excavation and completely sealed all the leaks. This prevented further washouts and allowed welding work to resume. The tank occupying the excavation site is now underneath the Al Oerter Recreation Center and several playing fields.

Leaks through the tieback anchors used in excavation of an 80-ft-deep pit for the Flushing Bay CSO prevented welding. Note the water streaming from the lowest row of anchor plates. The leaks were ultimately sealed with Prime Resins polyurethanes.