- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

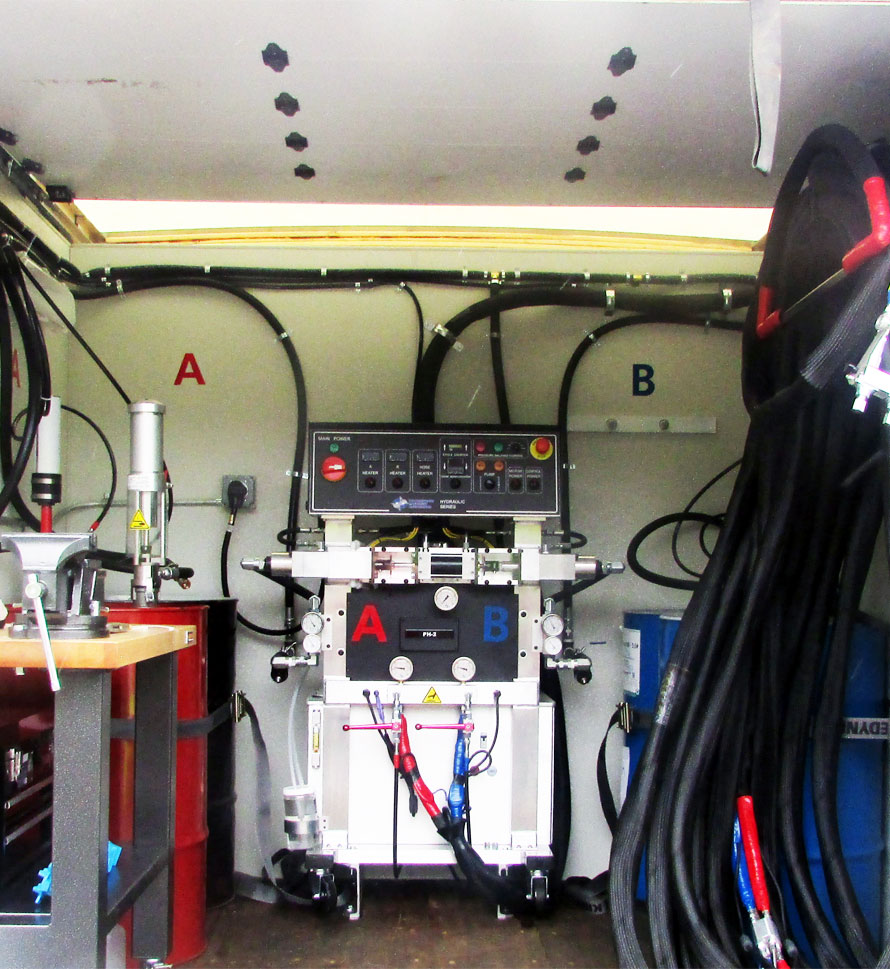

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Slab Lifting Pages

Polyurethane foam fills voids and levels an industrial concrete floor

Contractor: Merco Geopolímeros

Client: Beverage bottler, state of Minas Gerais, Brazil

Problem:

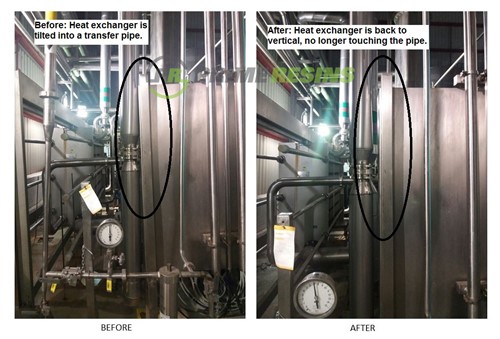

The client is a major beverage manufacturer in Brazil. One of its plants in the state of Minas Gerais experienced settlement of the floor under tanks full of 30,000 liters of liquid (nearly 8,000 gallons). The tank, supported by four legs, sits on a concrete pad. One corner had settled about 2 inches; thus, the tank was leaning away from its neighbor slightly. The facility manager was concerned that further settlement that would undermine the integrity of the floor and the stability of the tanks. Exploratory holes and a cut out revealed a 1-inch void under the slab. A second area under a heat exchanger also settled due to a void.

Solution:

Paulo Romeiro of Merco Geopolímeros recommended filling the void and lifting the slab with Precision Lift 4.0#, a high-density polyurethane structural foam from Prime Resins. Merco engaged on-site technical support from Prime Resins, who advised the best approach.

How they did it:

Our technical rep recommended an injection pattern that would essentially create a dam with cured grout around the lift site. Technicians drilled and injected a hole pattern in a line adjacent to the tank to create a foam barrier so that material would stay under the area that needed lifting. They drilled and injected two additional holes on the other side of the legs beneath the tank with long, slow shots to create a dam on the other side. Next, they injected one hole equidistant between the two legs on the settled side. Then they lifted one corner of the slab about an inch.

The on-site engineer decided to stop at this point because the slab was only about 5 inches thick, so he worried about breaking the slab. In addition, the base of the tank shifted slightly during the lift and he didn’t want it to move further. He knew that the void was filled, and the 1-inch lift was enough to stabilize the tank to his satisfaction.

The crew injected a second location under a 2000-lb heat exchanger and lifted it 4- 5 inches (10-12 cm) back to level with no complications using Precision Lift 4.0#. Then they tackled a third location: a simple soil stabilization and void fill using Prime Flex 920, a hydrophobic structural polyurethane foam. They created a base of cured 920 that compacted the soil and then filled the void above it as preventive maintenance to avoid settlement problems down the road.

Unpleasant surprise:

Thankfully Merco stocked more material than they expected to need because an emergency project cropped up while they were on site. Six months previously during the site assessment, they explored an area near a floor drain. They did this because that type of location had settlement problems at another of the bottler’s facilities. No issues were found at the time: There was good soil compaction and no visible void.

Now, however, there were three cracks in the concrete floor converging at the base of a structural support column. They could see a slight dip in the floor just looking at it without any levels. The engineer consulted with facility management who immediately gave permission to stabilize the soil and fill the void. The crew angle-drilled holes and used 13-foot (4-meter) probes to get underneath the base of the pillar. The void was so big or the substrate so soft that they pumped 80 gallons of Prime Flex 920 until refusal.

Outcome:

The crew fixed all areas of concern plus the emergency location to the engineer’s satisfaction. The client was pleased. Perhaps the best part for the client: Crews did all the work with zero shut down time in production.

This was the second project Merco Geopolímeros did for the same client. Consequently, the facility engineer asked all the company’s engineers to follow the project via WhatsApp updates he provided.

“The facility engineer told his colleagues this was a great opportunity to see something revolutionary in Brazilian engineering,” said Romeiro, partner and director of commercial operations for Merco Geopolímeros. “The client was full of praise and thanks for the results.”

Alternatives

The only alternative at this point was to move equipment, remove the concrete, compact the soil, and replace the concrete. Facility managers had already tried mudjacking with flowable fill, but that failed. The weight of the cementitious fill only aggravated the problem of a weak substrate and settled again soon after.

The hard cost of replacement materials and labor would be cheaper. However, the lost productivity that a plant shutdown would require to do that would cost hundreds of thousands of dollars.

Void filling and slab lifting with foam were a far more economical option in the long run.