- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

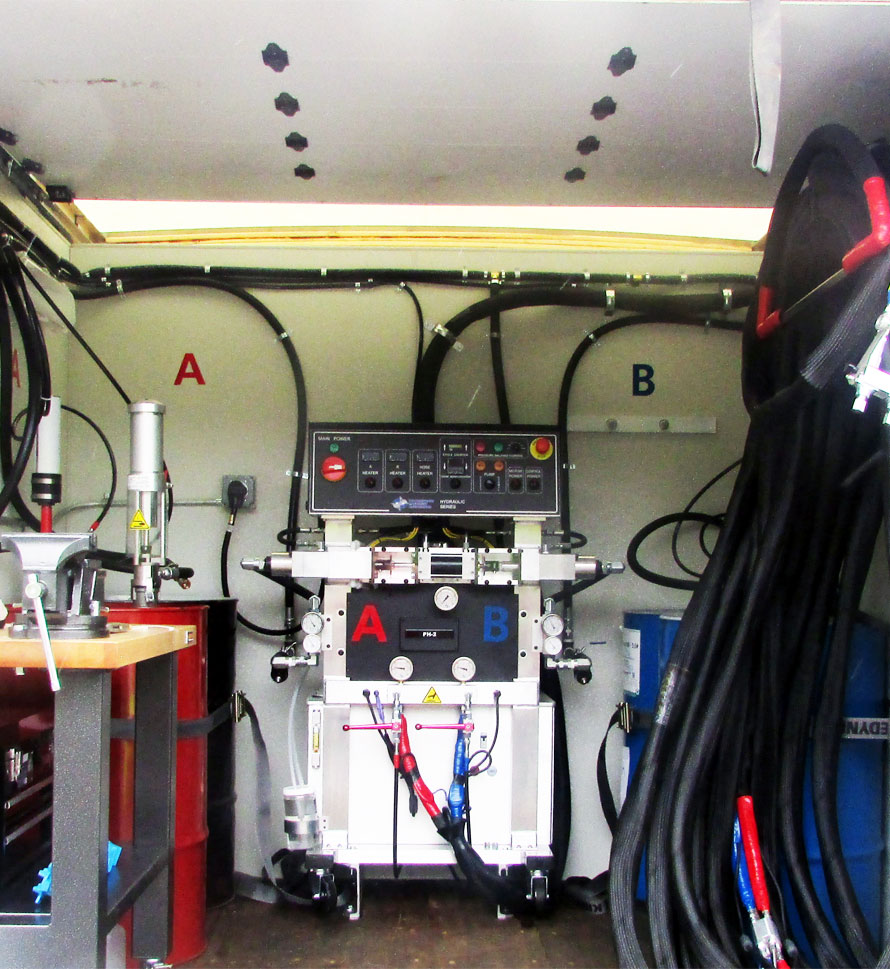

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Soil Stab & Void Fill Pages

Void fill of culvert washout with polyurethane foam

Client: N.C. Department of Transportation

Contractor: Applied Polymerics Inc., Mt. Airy, NC

Hurricane Matthew left a path of destruction in its wake up the East Coast. North Carolina was hard hit by storm-related flooding. Waters continued to rise in the days after the storm as flood waters receded elsewhere, draining to lower points. That included Lumberton, N.C., located 70 miles southeast of Wilmington in the coastal plains region of the state.

Problem:

Approximately six miles north of Lumberton there is a triple barrel box culvert under I-95. Each barrel is 12’ x 12’, so essentially there is a 36’-wide culvert under the highway. Storm-related flooding caused a major washout underneath the inlet end, leaving a huge void threatening the culvert’s integrity. That, in turn, would lead to a compromised highway in the long run. The North Carolina DOT completely shut down I-95 there for a time due to flooding. When flood waters receded, just one lane opened; the lane above the void remained closed.

Solution:

NCDOT tried filling the void in-house with cementitious grout over a weekend, which was not successful. That Monday NCDOT officials hired one of its contractors, Applied Polymerics, to solve the problem. They opted to fill the void with Prime Flex 985 LX20 Fast, a highly expansive two-component polyurethane. The Fast formulation reacts in 12 seconds versus 68-70 seconds and reaches full rise at 65-85 seconds.

“We needed to use LX20 Fast because we needed it to set up quickly, otherwise the water current would have just washed it away,” said Scott Kammerer of Applied Polymerics. “We like 985 because of its structural capabilities.”

Applied Polymerics lived up to its promise: “Whatever It Takes.” That evening one of its crews picked up material from Prime Resins just east of Atlanta and started work on Tuesday morning with a second crew.

Complicating factor

The flood level of the water created a nearly impossible work site, essentially an underwater grouting job. To preserve as much material as possible and to ensure the grouting technicians didn’t have to work in chest-high water, they installed a cofferdam of corrugated pipe. They secured the pipe with joists against the culvert ceiling and sealed it at the bottom.

“We worked closely with the DOT,” said Kammerer. “We worked with their dive team on the cofferdam and the DOT provided a crane. Crew members from the DOT were there nearly all the time we were. It was a good partnership.”

Crews worked around the clock Tuesday until Friday. An NCDOT engineer allowed both lanes to open for the weekend and give crews a respite. Officials closed one lane again Monday afternoon so grouting work could continue. Crews worked around the clock again until completion on Wednesday.

Outcome:

The void was more than double the original estimated 80 cubic yards. In the end, it measured between 180-200 cubic yards. Prime Resins ensured crews had the material they needed when they needed it.

“The manufacturer came through with material as needed—it was always there on time,” said Kammerer.

Crews filled the void and NC DOT officials opened I-95 to normal traffic.

Alternative:

Since cementitious grouting was unsuccessful, replacement was the only remaining option, a horrifically expensive and disruptive undertaking. Void filling with Prime Flex 985 LX20 Fast saved North Carolina taxpayers untold dollars and inconvenience.

A cofferdam sealed at the bottom minimized the flood waters so techs could inject polyurethane grout under the culvert to seal the massive void.