- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

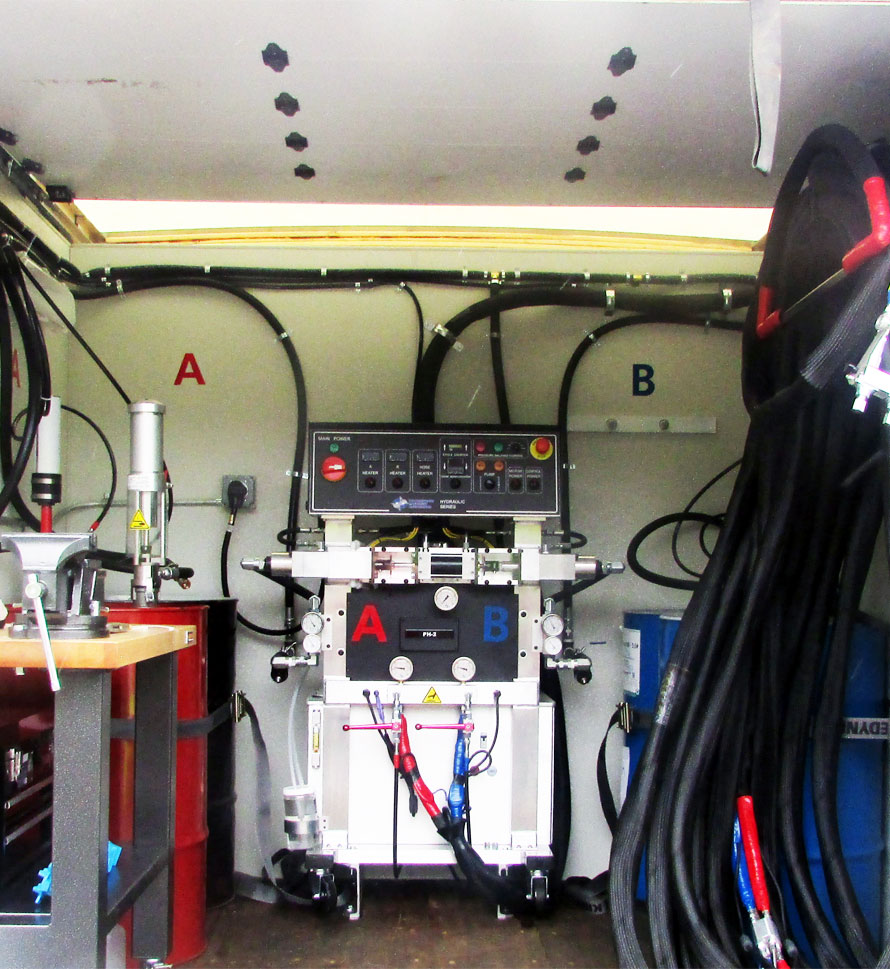

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

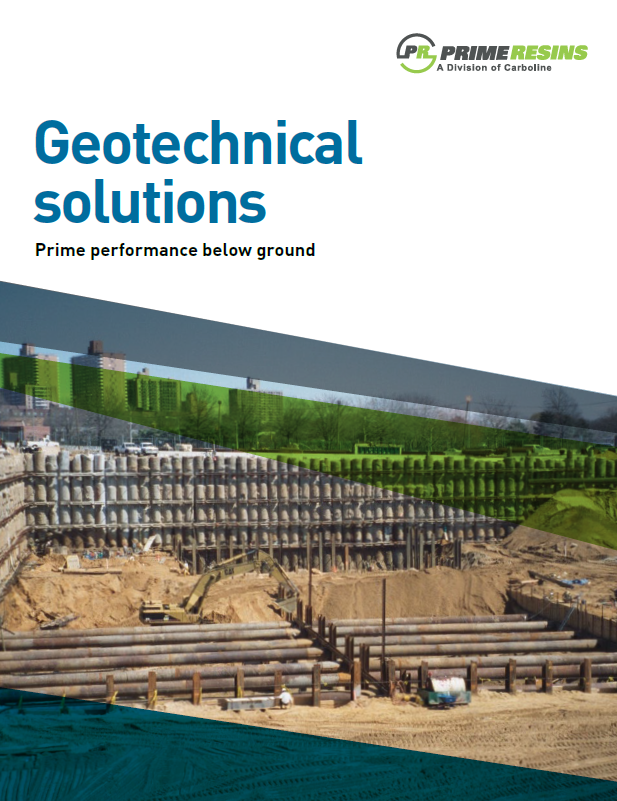

Prime Resins is proud to offer solutions for many varied geotechnical applications.

TUNNELING:

Prime performance below ground: grouting for stability, safety and success

Grouting non-cohesive soils and karst areas prior to and during boring is critical in stopping water flow and preventing collapse or settlement of the boring zone. Grouting provides a stable shell or crown for the Tunnel

Boring Machine (TBM) to pass underneath, minimizing the likelihood of wash-out or face collapse, potentially causing settlement of the ground or structures (railroad tracks, roads, etc.) above.

Grouting is also useful at entrance and exit pits for water stop and preventing soil collapsing. Prime Resins’ permeation grouting solutions present less stress and damage to cutterheads as opposed to other grouting solutions such as slurry or sodium silicate.

UNDERPINNING / FOUNDATION SUPPORT:

Non-disruptive underpinning

Prime Resins’ grouting solutions can be used to provide underpinning support of existing structures. This can typically be accomplished with little to no disruption to operations, job site or surrounding environment.

Whether used to stabilize existing buildings or new construction, underpinning by means of permeation grouting is an ideal solution to control sloughing and avoiding settlement. Permeation grout strengthens and stabilizes subgrade soils and significantly increases bearing capacity of the soil without excavating the existing footing. Permeation grouts can also be used to support and strengthen helical piers. If lifting the foundation is required, Prime Resins offers Precision Lift® polyurethane foundation lifting solutions as well.

Case study: 1028 Market St. - San Francisco, California

HAZARDOUS WASTE AND WATER CONTAINMENT:

Grouting solutions to stop leaks, seal voids, and contain hazards

Chemical grouts can be injected around and underneath water sources or hazardous waste to contain and stop leaching through loose soils and voids. Filling voids and binding loose soils forms a subsurface barrier or wall of treated soil that will contain water or hazardous waste and eliminate migration.

Containing hazardous waste

While subterranean soil remediation is costly, the public health and environmental costs, especially if the contamination may reach ground water, is exponentially more costly to address. Depending on the Federal EPA corrective action plan (CAP), the State EPD CAP or relevant authority; permeation grout can provide a longterm solution, with no further corrective action required.

Alternatively, to alleviate the cost and inconvenience of intensive long-term monitoring, excavating the entire plume may be the optimum solution.

Containing water sources

These grouting solutions can also be used to contain water by filling voids and binding loose soils to stop leaks in levees, earthen damns or seepage cut off walls.

PRE-EXCAVATION:

Protect adjacent structures with pre-excavation soil stabilization

Excavation support with chemical grout is a method of supporting structures and soil adjacent to planned excavations. Chemical grout turns loose soils into stable soil, allowing for a safe excavation without damaging adjacent buildings or structures.

Solidifying soils before excavation

Excavation support is needed for subsurface trenching when working with soft soils and/or soils with high water tables. Permeation grout is a very low viscosity grout, designed to penetrate fine silts, sands, course sands and top soil to a desired depth. This could be below the water surface, below the water bed, or all the way to bedrock. The grout remains fluid until polymerization, allowing for excellent penetration. It is ideal for geotechnical use in humid environments and sandy soils, ensuring that nearby structures avoid wash-out during trenching.

Case Study: Pre-excavation grouting - Interstate highway, USA

ROAD & BRIDGE REHABILITATION:

A solid substrate is fundamental to roadways and bridges

Over time, forces of nature take their toll. Decomposing soils, erosion, freeze-thaw cycles and groundwater migration can break down this foundation. This is a common occurrence in causing sinkholes in roads and settling at bridge approaches and bridge abutments. Injecting chemical grouts into loose soils, voids, pores and fissures will strengthen the earthen substrate and provide watertight encapsulation. DOTs are responsible for many structures requiring stabilization and void filling. Our products meet or exceed existing DOT specifications for all geotechnical applications.

Case Study: Highway stabilization, I-40, North Carolina

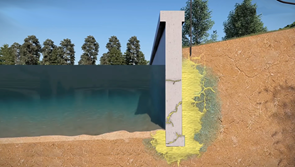

SEAWALL / BULKHEAD REPAIR:

Revive bulkheads and seawalls with precision grouting

Seawalls or bulkheads can be repaired with chemical grouts without the use of excavation or heavy equipment, with minimal disturbance and often times without permitting. Injecting hydrophobic grout behind the seawall will seal off erosions points, often times at the footer, seams and joints. The grout also fills voids and stabilizes loose soil, ultimately restoring the integrity of the structure at a fraction of the cost of replacement.

Case Study: Marina Project - Panama City Beach, Florida