- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

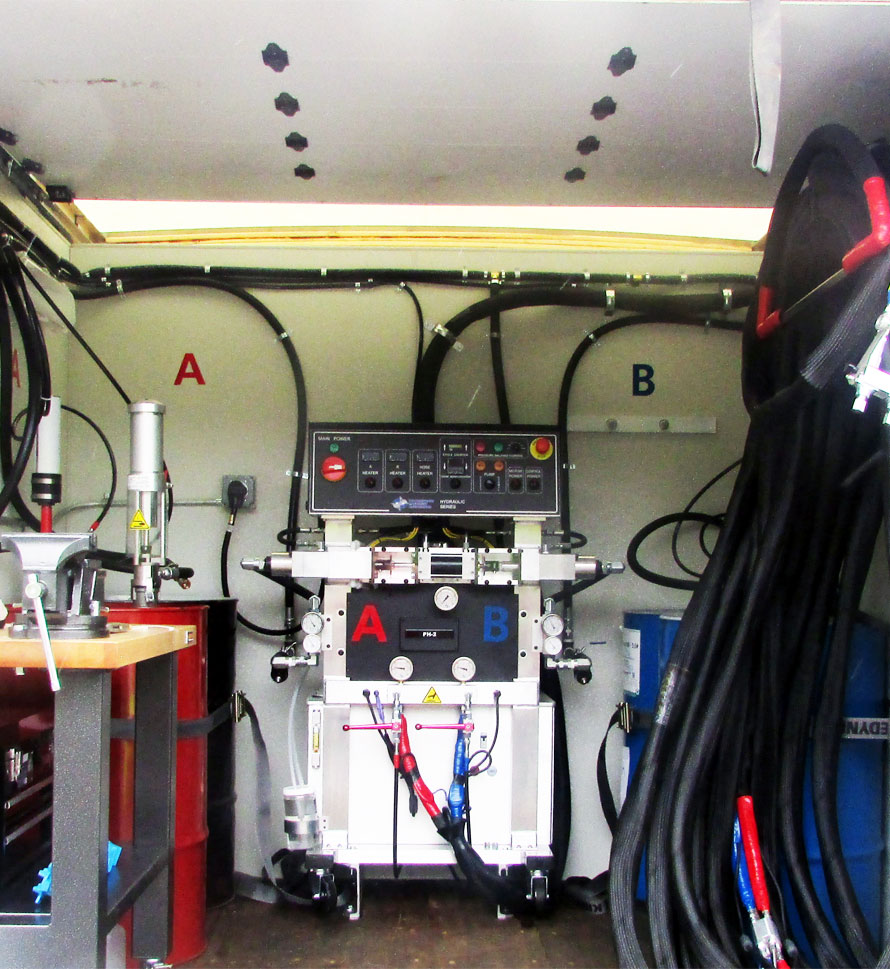

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Case Studies

- Contact

Seawall Repair with Chemical Grouts

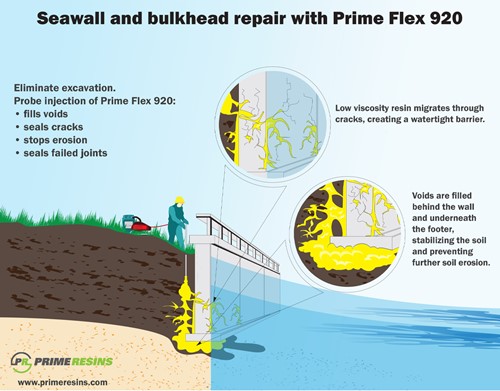

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

A property owner is plagued by a failing seawall. Soil washes away with every wave or tidal cycle through gaps in or under the wall. Maybe the wall joints are failing. Perhaps the footer no longer meets a solid foundation.

The symptoms are clear

The ground is caving in behind the wall. Voids are visible. Sinkholes are forming. Nearby walkway, sidewalk, patio or pool deck slabs have settled, resulting in trip and fall hazards. Unseen consequences can include compromised foundations of adjacent structures.

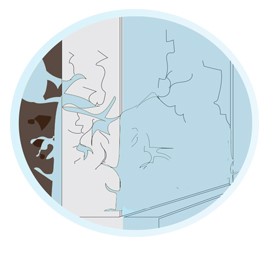

These symptoms are caused by erosion of the ground behind the wall. Typically, this is caused by leaks in the wall, improper drainage of land-side runoff, or ground behind the wall that was not sufficiently compacted during construction. The latter can happen when the original contractor worries about putting too much force against the wall and consequently doesn’t tamp the earth hard enough. Over time that ground will settle or will get saturated and mushy. Either will result in voids and erosion, undermining the integrity and effectiveness of the wall. Cracks or failing joints in a seawall can cause erosion behind the wall, compromising the integrity of the structure (as seen in the illustration below.)

Seawall Repair Options

You could fill voids with dirt and aggregate or a cementitious fill. But this won’t remove the reason there is erosion or settlement in the first place.

You could replace some or all of the wall. That is a major construction project that is highly disruptive to the property owner and possibly to the environment. An environmentally sensitive area could mean an extensive (and expensive) permitting process, delaying remedy by weeks or months. Depending on the location, you could be looking at needing to use a barge or crane to do the construction.

There are absolutely times when replacement is the best or only option. That is often not the case though.

What if?

What if you could:

- Seal the failing joints in a wall

- Stabilize loose, saturated soil

- Fill voids behind the wall without adding huge weight to a weak substrate

- Create a watertight barrier behind and under a wall, all without excavation?

And what if you could do all of that with material so eco-friendly that it is certified for contact with drinking water?

Yes, you can

You can do all those things with polyurethane injection resins from Prime Resins. For 35 years, our products have been used to stabilize soil, seal leaks, and repair concrete—including more than 200 seawalls and bulkheads.

FOR THE PROPERTY OWNER

If you are a property owner in need of seawall or bulkhead repair, call us for referral to a trained technician in your area. Go here to find the contact for your location.

One example

Imagine coming home from vacation to find your backyard disappearing into a sinkhole beside the bulkhead. That’s what happened to one homeowner on Lake Harris in Lake City, Florida. The bulkhead is only 15 feet from the foundation, so she had visions of her very expensive home falling into the lake. Steps were taken to address several issues. The large voids were filled and the failing wall joints were sealed using Prime Flex 920. The product is a hydrophobic polyurethane resin that is certified to comply with NSF/ANSI Standard 61 for contact with potable water.

The homeowner was thrilled with the results, which will last decades under normal circumstances. Her short-term options would have saved her money upfront, but the long-term cost of seawall failure or foundation damage to her home would have been 400% to 500% higher than what she spent on permeation grouting with Prime Flex 920.

Here are your options

|

|

Hydrophobic single-component polyurethane resin with a very low viscosity that reacts with moisture when injected into soil forming a rock hard, water-tight mass. Used to stabilize loose soil or sand, stop underground water flows and seal leaking seawalls. |

|

|

|

Independently tested and certified as compliant with NSF/ANSI Standard 61.5 for contact with potable water. Hydrophobic, super low viscosity polyurethane that reacts with water and expands to form a closed cell, watertight, rigid foam. Used for filling voids and for permeation grouting of loose soils to consolidate soil particles and stop erosion. |

|

|

|

For filling large voids and voids under load-bearing concrete structures. Versatile, two-component, low exotherm polyurethane foam used to fill voids, stabilize soil and underseal concrete slabs. Very low viscosity allows for moderate permeation. Independently tested and certified as compliant with NSF/ANSI Standard 61.5 for contact with potable water. |

|

|

|

Used with oakum for sealing large joints or defects in concrete seawalls. Hydrophilic resin that reacts with water, so excellent bond with concrete for sealing cracks and failed seawall joints. Independently tested and certified as compliant with NSF/ANSI Standard 61.5 for contact with potable water. |

|

|

|

Multi-component acrylate resin system that forms an elastomeric gel when cured. Recommended for permeation grouting in extremely fine, “sugar” sand. Adjustable set time gives flexibility and allows for thorough permeation. Independently tested and certified as compliant with NSF/ANSI Standard 61.5 for contact with potable water. |

New to chemical grouting?

- No specialty equipment required. Injecting polyurethane resins requires only a simple lightweight electric pump such as a Titan 540 or 640 and probes to deliver the material into the void. (The AR 800 acrylate does require equipment with all stainless steel wetted parts.)

- Training is available. We provide on-site technical service or training on a fee-for-service basis. Twice a year we offer the Prime Resins Chemical Grouting Institute at our Atlanta-area headquarters.

Save your client’s seawall. Rescue their property from the sea or lake. You can be the hero who offers them a permanent solution to their erosion problem at a fraction of the cost and disruption of replacement.

Call one of our technical consultants today at 800-321-7212 for more information on seawall repair or fill out the form found at the bottom of the page here.