- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

- Leak Repair

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

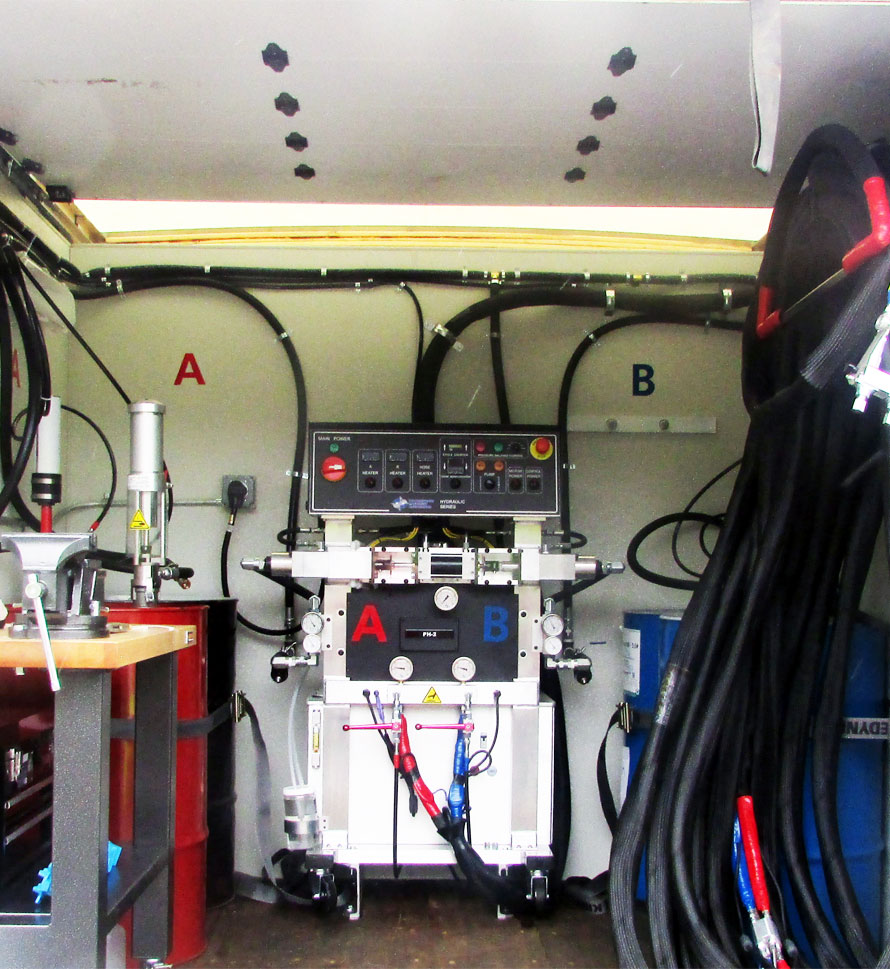

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- Floor & Joint Repair

- Waterproofing & Secondary Containment

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Seawall Repair Pages

Void fill behind a sheet pile retaining wall at busy port

Client: Jacksonville Port Authority

Contractor: Foundation Professionals of Florida

The Port of Jacksonville (Florida), known as JAXPORT, is among the busiest seaports on the eastern seaboard. With three cargo facilities and a cruise passenger terminal, JAXPORT moved 8.7 million tons of cargo, nearly a million containers, and its two millionth cruise passenger in 2016.

Problem:

There is a sheet pile retaining wall under the bridge to the passenger terminal that experienced corrosion. This created points of penetration through the wall, resulting in erosion. The soil loss created several voids behind the wall. Eventually, further erosion would likely compromise the bridge.

Solution:

The port engineer specified chemical grouting to fill the voids. Foundation Professionals of Florida opted to use Precision Lift 4.0, an expansive two-part polyurethane structural foam used to fill voids and lift concrete. The contractor does a lot of seawall work and typically uses Prime Flex 920, a highly expansive hydrophobic polyurethane foam. In this case, however, they opted for the Precision Lift 4.0# to achieve a high-strength cured foam with less hydraulic force.

“We decided that 4.0 was a better choice in this situation,” said David Brown of Foundation Professionals. “The engineer was concerned about expansive pressure against the sheet pile. The Precision Lift gave us foam with the structural integrity and compressive strength we needed with less hydraulic force than Prime Flex 920.” The crew did about 10 days of work over the course of a month from a boat. They injected the chemical grout through the wall using Bang-in Ports.

Challenges:

The biggest challenge was working around the port schedule between the cargo and the cruise passengers. JAXPORT is in the top two or three ports in the U.S. for vehicle imports and is a year-round port for Carnival Cruise Line.

Outcome:

The crew successfully filled the voids and sealed the penetrations in the sheet pile without interrupting port operations.

“It was neat to work on a project where we affected so much daily traffic,” said Brown. “This is the main bridge coming into the terminal with 15,000 cruise passengers every week. We were able to provide a solution that did not require any shutdown time for the busy port.”