- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

- Leak Repair

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

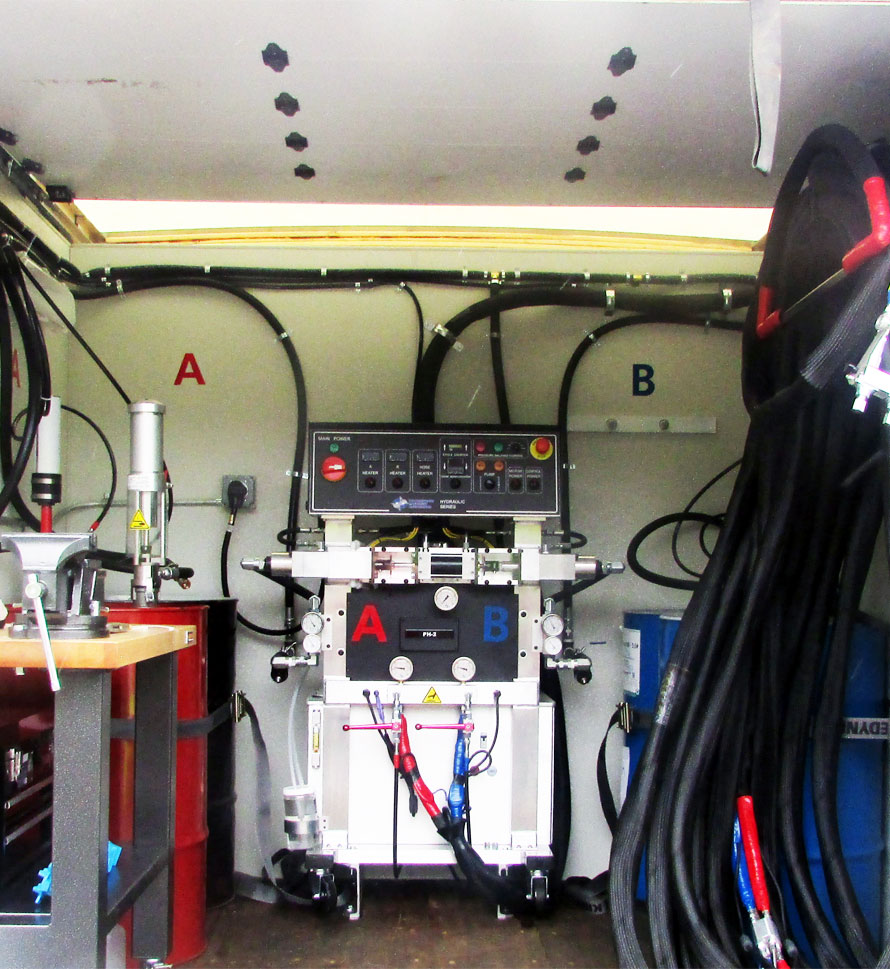

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- Floor & Joint Repair

- Waterproofing & Secondary Containment

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Case Studies- Soil Stab & Void Fill Pages

Sinkhole Repair: Chemical grouting eliminates need to excavate pavement at busy port

Client: The Port of Palm Beach, West Palm Beach, Florida

The Port of Palm Beach had a problem on its hands when a sinkhole developed under one of its main traffic routes. A leaking sewer line and storm water main drain caused erosion, resulting in a 4-foot-wide area of asphalt sinking approximately 6 inches. Beside causing major wear and tear on trucks and other equipment driving across it, a worsening dip could pose a dangerous situation.

Solution:

The contractor opted for probe grouting to seal the leaks with an expansive polyurethane resin. This eliminated the need to excavate the pavement. There was no need to shut down complete access to the port. The crew needed to cordon off only the immediate work area, allowing full function of the port.

The process:

The grout technician drilled holes through the asphalt and inserted an injection probe down to the leaking pipe. He injected Prime Flex 920, a hydrophobic polyurethane resin, around the pipe. The 920 sealed the leak by forming a closed-cell, watertight mass around the pipe. The expanding foam filled the voids created by the leaks. The technician continued resin injection in several “lifts” or installments between the pipe and the surface. This stabilized the soil and created a rock-hard column that increased the load-bearing capacity of the substrate.

At this point, following soil stabilization, the crew injected Precision Lift 4.0#, a high-density polyurethane structural foam, compacting any remaining loose soil and lifting the asphalt 4 1/2 inches. Any further lifting threatened to rupture the asphalt due to its softness and flexibility (relative to concrete). A slight dip remains where the sinkhole was, but does not impede normal operations of the busy port.

Asphalt is often not a great candidate for lifting because its relative softness and flexibility can result in tearing or rupturing of the asphalt. Port officials did not want the major disruption to operations caused by replacing the asphalt, so in this case it was a good solution.

Outcome:

The contractor sealed the leaks, stabilized the soil, and lifted the sunken asphalt nearly level. They completed the job within six hours.

The alternative:

The typical method of repairing this type of problem would include:

- shut down the road,

- cut out the asphalt,

- dig down to the pipe,

- repair the leak in the pipe,

- backfill the hole,

- replace the asphalt.

Repair costs of this approach are in the tens of thousands of dollars. The contractor solved a problem and fixed a potentially dangerous situation for the Port of Palm Beach at a fraction of the cost. In fact, the client said this solution saved him $40,000 and the major disruption of an excavation repair.