- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

- Leak Repair

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

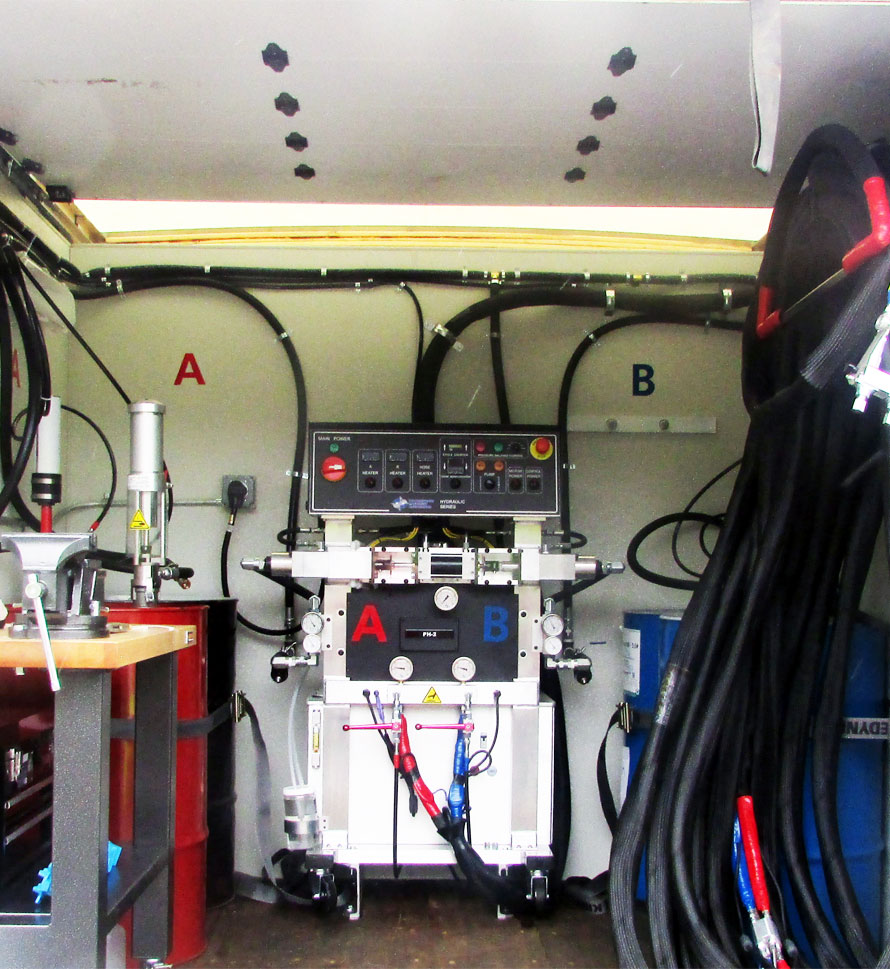

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- Floor & Joint Repair

- Waterproofing & Secondary Containment

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Case Studies

- Contact

Prime Practices

Applying Protective Epoxy Coating

This document covers the processes of surface preparation, priming and installation of a protective epoxy coating system.

Problem: Heavy use, aggressive chemicals or exposure to elements can wear away the concrete surface.

Solution:

Application of a protective epoxy coating can extend the life of the surface.

Surface preparation is considered to be the most important step of any resinous protective coating application. Improper surface preparation could turn what seems to be a simple process into a lengthy, difficult repair. Please refer to Prime Practices “Surface Preparation” for complete details on preparing the surface.

Material Preparation:

Store material overnight to precondition to 70 to 80 degrees F (21 to 26 C) prior to use. Pre-mix each component prior to combining. “B” component contains pigments, fillers and other chemicals that settle over time. Failure to properly pre-mix will result in uncured or improperly cured material or color variances in the cured material.

Mixing Procedures:

Only mix the amount of material you can use within the stated pot life. Use a slow speed mix drill and mixing paddle. Avoid introduction of air into the mixed material by controlling the speed of the drill and keeping the mixing paddle at the bottom of the pail. Scrape the sides and bottom of the pail during mixing.

Note: Large batches of epoxy will set up faster than smaller ones. Only mix the amount of material you can use in the given pot life of your coating system.

Surface imperfections

Fill pock holes, divots or other surface imperfections with a fast cure patching mortar such as Prime Resins Floor Fix for horizontal surfaces, or Prime Gel 2000, 2100 or 2500 Quick Bond for either vertical or horizontal surfaces. Protective coating systems are only as sound as the concrete they are applied to. All unsound concrete should be repaired or replaced prior to protective coating applications. Be sure to allow cementitious repair mortars to fully cure prior to applying coating.

Priming the surface:

Use Hydrolock (water-based primer sealer) prior to installing coating system. Mixing preparation and procedures apply. Apply primer at a rate of 200 – 300 square feet per gallon (18.58 – 27.87 sq. meters per gallon). Primer will appear white or milky immediately after placement. Avoid allowing primer to pond in low areas when applying to horizontal surfaces. Primer is considered dry and ready to coat as soon as it turns clear (1 to 3 hours), do not wait longer than 24 hours to apply coating system.

Apply coating system

Follow all previously mentioned material preparation and mixing procedures. Protect adjacent structures by applying tape along the edges of the intended area to be coated along with any penetrations. Use a cut-in brush to coat edges prior to rolling complete area. Use a 1/4” – 1/2” mohair roller cover and notched squeegee to apply epoxy coating system at a rate of 80 square feet (7.4 sq. meters) per gallon (20 mils). Two coats are recommended. Allow 1 to 3 hours for first coat to initially set then apply second coat. The first coat must be tack free and firm enough to walk on without leaving footprints. Do not wait longer than 24 hours prior to installing a second coat. Any air bubbles that form in the coating can be removed by back rolling with a tined (spiked) roller before the coating is tack free. Use spiked shoes to minimize damage when walking on uncured coatings.

For a non-slip surface:

Do a small test area first to determine proper aggregate size.

Broadcast aluminum oxide or oven dried sand aggregate into the first coat while it is still tacky. It is recommended to use the size aggregate appropriate for the profile required, use smooth or non-angular (few sharp edges) aggregate or follow manufacturers recommendations. After initial cure, sweep or blow off excess aggregate and apply second coat.

Safety Considerations:

- Wear protective clothing, chemical resistant gloves, and safety goggles at all times.

- Wear safety glasses and dust mask when drilling, sawing, or grinding.

- Carefully read MSDS prior to handling any chemical.

- Keep first aid kit (eye wash, bandages, etc.) present on site with easy access.

Materials List:

- Floor Fix or Repair Mortar

2. HydroLock (water-based primer sealer) - Epoxy Coating System (Prime Coat 4300, Prime Coat 4500 Ultraclear)

- Prime Gel 2000, 2100 or 2500 Quick Bond.

Equipment List:

- Slow speed mixing drill

- Mixing paddle

- Paint roller with broom type handle

- 1/4” – 1/2” mohair roller covers

- Paint tray with liners

- Tined roller

- Mixing pails (5 gallon)

- Notched squeegee with broom handle

- Spiked shoes

- Spiked roller

Accessories List:

Aluminum oxide or suitable oven dried sand aggregate

Related:

Prime Practices “Surface Preparation”