- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

- AR 800

- Conduit Seal Kit

- PR10L ACLM

- Soakum Oakum Kit

- Prime Flex 900 XLV

- Prime Flex 910

- Prime Flex 920

- Prime Flex 940

- Prime Flex 985 LX10

- Prime Flex 985 LX20

- Prime Flex 985 5.0

- Prime Flex 985 5.0 Fast

- Prime Flex Hydro Gel™ SX

- Prime Plug 1, 2 & 3

- PrimeCem MSM

- PrimeCem CAM

- PR10 ACLM (granular)

- Prime Flex Hydro Gel™ EXP

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

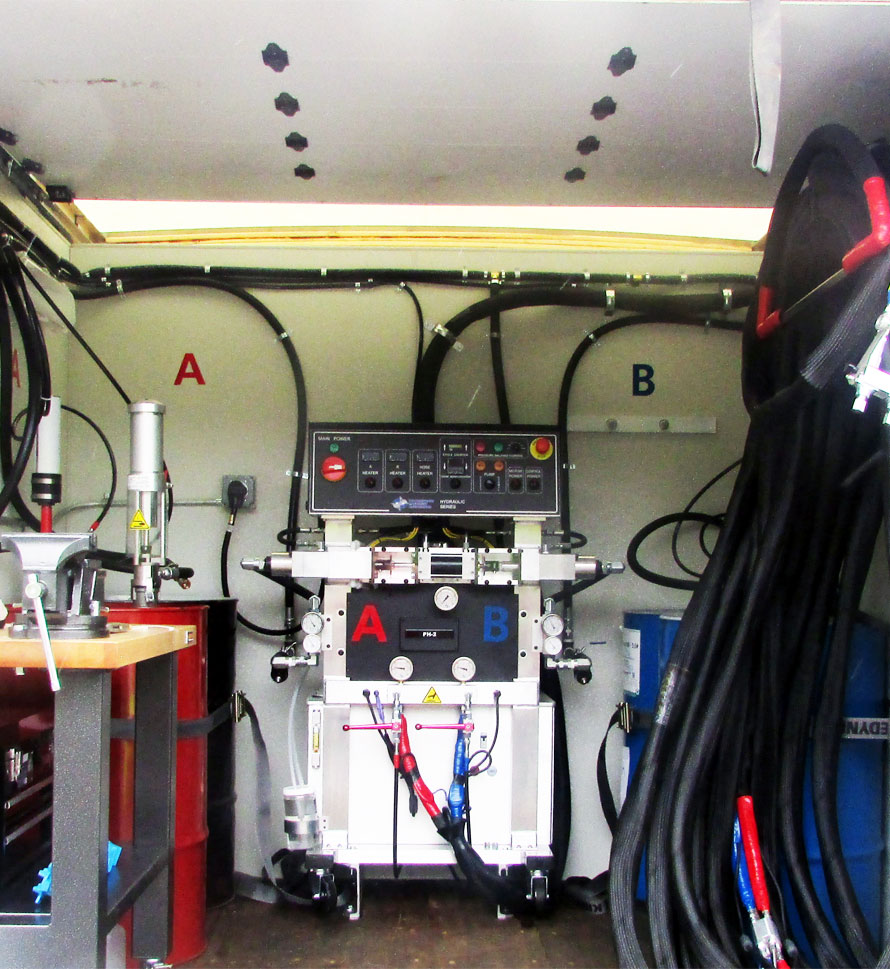

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- JackJaw Soil Probe Extractor

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Case Studies

- Contact

Prime Practices

Concrete Protection: Surface Preparation

Scope of Work: Cleaning, etching, shot blasting or brush blasting a concrete surface in preparation of installing an epoxy or polyurea protective coating.

Problem: The success of your protective coating system is dependent on proper surface preparation. Improper surface prep could result in spot delimitations or complete failures and overall shortened life of the system.

Solution:

The following guides will help assure maximum performance of the coating system and satisfactory coating adhesion to concrete:

- Cure – Concrete must be cured prior to coating application. Cured is defined as concrete poured and aged at a material temperature of at least 75°F (28°C) for at least 30 days. The pH of the surface should be between 6 and 9.

- Moisture – (Reference ASTM D4263) Concrete must be free of moisture as much as possible (moisture seldom drops below 15% in concrete). Test for moisture or dampness by taping the four edges of an 18-inch by 18-inch plastic sheet (4 mils thick) on the bare surface, sealing all of the edges. After a minimum of 16 hours, inspect for moisture, discoloration or condensation on the concrete or the underside of the plastic. If moisture is present, the source must be located and the cause corrected prior to coating.

- Temperature – Air, surface and material temperature must be at least 50°F (10°C) during the application and until the coating is cured.

- Contamination – Remove all grease, dirt, loose paint, oil, tar, glaze, laitance, efflorescence, loose mortar and cement by the recommended methods A, B, C or D listed below.

Imperfection may require filling with a material compatible with Prime Resins coatings. - Concrete Treatment – Hardeners, sealers, form release agents, curing compounds and other concrete treatments must be compatible with the coatings or be removed.

- Concrete – Blast Cleaning

(Reference ASTM D4259) Brush blasting or sweep blasting includes dry blasting, water blasting, water blasting with abrasives, and vacuum blasting with abrasives. For horizontal surfaces, shot blasting is preferred.

- Use 16 – 30 mesh sand and oil-free air.

- Remove all surface contamination (ref. ASTM D4258). See method D below.

- Stand approximately 2 feet (.6 meters) from the surface to be blasted.

- Move nozzle at a uniform rate.

- Laitance must be removed and bug holes opened.

- Surface must be clean and dry (moisture check: ref. ASTM D4263) and exhibit a texture similar to that of medium grit sandpaper. Achieve a surface profile of 3 (Reference ICRI Technical Guideline #03732).

- Vacuum or blow down and remove dust and loose particles from the surface (ref. ASTM D4258).

- Concrete – Acid Etching

Etching or washing the concrete with acid opens the pores of the concrete and alters the surface of the concrete to allow for better adhesion of coatings.

- Remove all surface contamination (ref. ASTM D4258).

- Wet surface with clean water.

- Apply a 10 – 15% muriatic acid or 50% phosphoric acid solution at the rate of one gallon per 75 square feet (7 square meters).

- Scrub with a stiff brush.

- Allow sufficient time for scrubbing until bubbling stops.

- If no bubbling occurs, the surface is contaminated with grease, oil or a concrete treatment, which is interfering with proper etching. Remove the contamination with a suitable cleaner (ref. ASTM D4258 or method D below) and then etch the surface.

- Rinse the surface two or three times. Remove the acid/water mixture after each rinse.

- Surface should have a texture similar to medium grit sandpaper.

- It may be necessary to repeat this step several times if a suitable texture is not achieved with one etching. Bring the pH (ref. ASTM D4262) of the surface to neutral with a 3% solution of trisodium phosphate or similar alkali cleaner and flush with clean water to achieve a sound, clean surface.

- Allow surface to dry and check for moisture (ref. ASTM D4263).

Concrete – Power Tool Cleaning or Hand Tool Cleaning

- Use needle guns or power grinders, equipped with a suitable grinding stone of appropriate size and hardness, which will remove concrete, loose mortar, fins, projections and surface contaminants. Hand tools may also be used.

- Vacuum or blow down to remove dust and loose particles from surface (ref. ASTM D4258 or method D below).

- Test for moisture or dampness by taping the four edges of an 18-inch by 18-inch plastic sheet (4 mils thick) on the bare surface (an asphalt tile or other moisture impervious material will also do), sealing all of the edges. After a minimum of 16 hours, inspect for moisture, discoloration or condensation on the concrete or the underside of the plastic. If moisture is present, the source must be located and the cause corrected prior to coating.

Concrete – Surface Cleaning

- The surface must be clean, free of contaminants, loose cement, mortar, oil and grease. Broom cleaning, vacuum cleaning, air blast cleaning, water cleaning and steam cleaning are suitable as outlined in ASTM D4258.

- Concrete curing compounds, form release agents and concrete hardeners may not be compatible with recommended coatings. Check for compatibility by applying a test patch of the recommended coating system, covering at least 2 to 3 square feet (.18 to .27 square meters).

- Allow concrete to dry one week before testing adhesion per ASTM D3359. If the coating system is incompatible, surface preparation per methods outlined in ASTM D4259 are required.

Safety Considerations:

- Wear safety glasses and dust mask when drilling, sawing or grinding.

- Wear protective clothing, chemical resistant gloves and safety goggles at all times.

- Keep first aid kit (eye wash, bandages, etc.) present on site with easy access.

- Carefully read MSDS prior to handling any chemical.

- Make sure no loose clothing can come into contact with moving mechanical equipment.

- Follow all OSHA confined space entry requirements.

- Dispose of all acids, chemicals, waste, slurry / grindings in accordance with all local, county, state/provinical and federal laws.

Materials List:

- Tape

- 18” x 18” plastic sheet

- Filling material

- 16-30 mesh sand (method A)

- Clean water (method B)

- 10 – 15% muriatic acid or 50% phosphoric acid solution (method B)

- Stiff brush (method B)

- Squeegee

- Wet vac

Equipment List:

Needle gun, power grinder or hand tool for grinding (method C)

Broom, air blast, vacuum, clean water or steam cleaner (method D)

Related: