- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

- Leak Repair

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

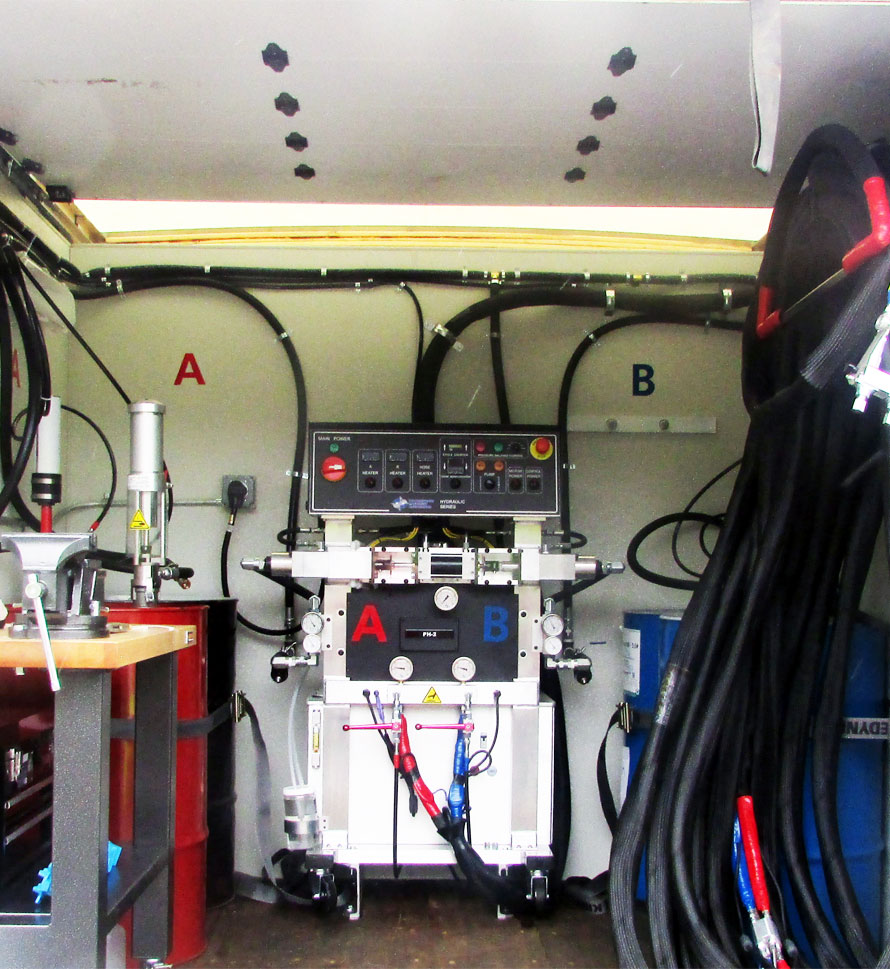

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- DPM30 Penetrometers

- Floor & Joint Repair

- Waterproofing & Secondary Containment

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Podcasts

-

Case Studies

- Contact

Prime Practices

Injecting Wet Cracks with Quick Mix Cartridges and Bang In Ports

Scope of Work: Sealing actively leaking 1/16” wide or wider cracks in concrete using Prime Flex 900 XLV Quick Mix cartridges.

Problem: Cracks in concrete walls (including basement walls, above- and below-grade water and sewer tanks, utility vaults, parking structures and other below-grade structures) allow water to migrate through the concrete exposing reinforcing steel to moisture––which may result in corrosion of the steel––and can result in unsightly water stains, efflorescence and spalling concrete.

Solution Steps:

• START WITH A VISIBLE CRACK

The surface of the crack may need to be cleaned with a mechanical grinder or a wire brush. Mineral deposits left by efflorescence can inhibit full penetration of the resin.

• DRILL INJECTION HOLES

See “Flushing Drill Holes and Installing High Pressure Ports” for detailed information.

• FLUSH INJECTION HOLES

See “Flushing Drill Holes and Installing High Pressure Ports” for detailed information.

• INSTALL PORTS AND FLUSH THEM

See “Flushing Drill Holes and Installing High Pressure Ports” for detailed information.

• SURFACE SEAL THE CRACK (IF NECESSARY)

Surface sealing a wet crack wider than 1/8” (.3 cm) can be done using hydraulic cement (Prime Plug 1, 2 or 3). Surface sealing a crack less than 1/8” wide may not be necessary. Once the surface of the crack has been mechanically cleaned, apply a 1/4” to 1/2” (.6 to 1.3 cm) thick band of Prime Plug to the surface 2” – 4” (5 – 10 cm) wide depending on the size of the crack. Allow material to harden for about 10 minutes before beginning the injection process.

Note: If the crack is dry, it may be surface sealed with any of the Prime Gel epoxy gel products.

• INJECT THE CRACK WITH PRIME FLEX 900 XLV

Always wear safety goggles, chemical resistant gloves and long sleeve shirt and pants when using Prime Flex grouts. See SDS before working with any Prime Flex product.

Install the zerk fitting on the port located at the lowest point of the crack for vertical applications or the first port working from left to right or vice versa for horizontal applications.

- Fill the empty side of the Quick Mix cartridge with water and replace the plunger cap.

- Put the cartridge into the gun and install the static mixer and secure with included retaining nut.

- Install the cartridge to zerk adaptor (Part # QMC-Z) by firmly pushing the end of the static mixer into the compression seal side of the adaptor.

- Connect the zerk coupler to zerk fitting of Bang-In port.

- Pull the trigger and dispense the grout into the crack.

- Continue injecting the grout until material begins to flow from the next port in line.

- Install the zerk fitting on the second port and continue installation of material; repeat at each port location in sequence until the entire crack has been injected.

• REMOVE THE PORTS

See “Flushing Drill Holes and Installing High Pressure Ports” for detailed information.

• PATCH THE INJECTION HOLES

The injection holes should be patched with an epoxy gel (Speed Bond #1 or any Prime Gel product) or a cementitious patching mortar such as Prime Plug.

• APPLY SURFACE SEAL (OPTIONAL)

Use an electric grinder with a grinding disc or wire wheel to remove any excess grout and clean the surface. Use caution as a wire wheel can “grab” the grout and be pulled from the technician’s hands. If possible, wait 24 hours prior to performing this step. Apply a band of Prime Gel 2200 Flexible to the surface of the crack to give a more attractive look to the surface and to act as a secondary barrier. Not for use as an exterior joint sealant.

Safety Considerations:

- Always wear safety goggles when drilling, grinding, flushing, injecting or handling resins.

- Always wear protective clothing, chemical resistant gloves and safety goggles at all times when handling resins. Blowouts can occur when injecting resins at high pressure. Prime Plug contains cement powder, which has a very high pH and may cause burns to skin or eyes.

- Carefully read SDS prior to handling any chemical.

- Be aware of potential electrocution hazards when working with power equipment in wet environments. Keep water away from electrical cords and electrical equipment.

- Make sure no loose clothing can come into contact with moving mechanical equipment.

- Follow all OSHA or comparable confined space entry requirements where applicable.

- Polyurethane resins contain isocyanates, which can cause respiratory irritation. Use mechanical ventilation in confined spaces.

- Keep first aid kit (eye wash, bandages, etc.) present on site with easy access.

Materials List:

- Prime Flex 900 XLV Quick Mix cartridges

- 3/8” Bang-In ports

- Cartridge to zerk adaptor

- Prime Plug 1, 2 or 3

- Prime Gel epoxy adhesive (optional)

Equipment List:

Rotary hammer drill

3/8” drill bit (of appropriate length)

Electric grinder with masonry or wire brush wheel

1:1 / 2:1 ratio manual cartridge gun #725 or air gun #700

Vice grips

Hammer

5/16” nut driver for zerk fitting

Related Documents: